It is the multi-function stone processing machine which adopted the most technology in domestic and foreign, combined with processing in current market. It can process in artificial stone, stone and ceramic plates in one production line for drilling, milling, profiling,grinding,polishing according to the different models.

Item NO.:

SMT3015/SMT3020Order(MOQ):

1Payment:

T/TProduct Origin:

chinaColor:

yellow & grayShipping Port:

xiamen portLead Time:

15 daysProduct Introduction

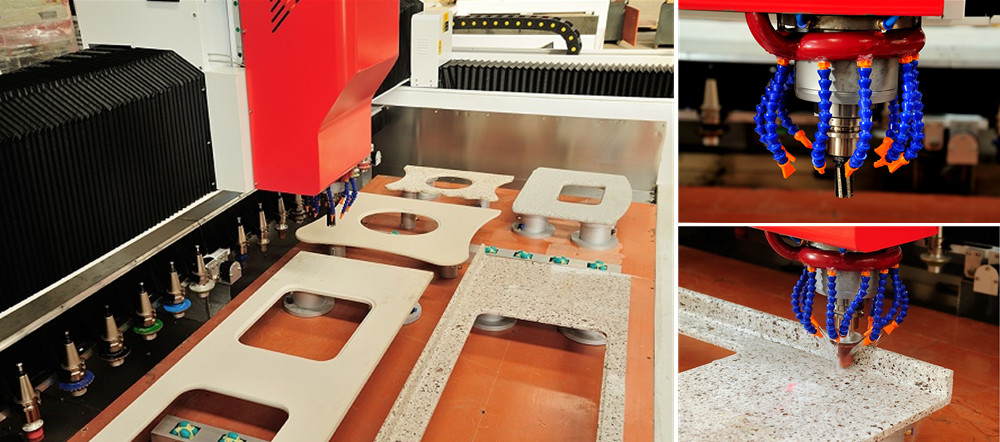

1. It is a multi-function stone processing machine which adopts both domestic and foreign technology. Combined with the processing methods in current market, it can process artificial stone, stone and ceramic plates in one production line for drilling, milling, profiling, grinding and polishing according to the different models.

2. It applies Gantry type structure, which is more strong and stable.

3. Main motor adopts high-speed spindle.

4. The movement speed is controlled by frequency converter.

5. It can change the tools automatically according to the processing steps.

6. The machine is combined with vacuum clamping.

7. It is simple to operate with fast processing speed and high precision.

Technical Parameters

| Model No | SMT3015/SMT3020 |

| processing Length | 3000MM |

| Processing Width | 1450MM/2000MM |

| Working Thickness | ≤35MM |

| Max traverse speed | 25000mm/min |

| Max working speed | 15000mm/miiK |

| Spindle | Taiwan mechanical spindle |

| Milling Cutter Diameter | Φ10-Φ25MM |

| Drilling Wheel Diameter | Φ10-Φ50MM |

| Shaping Wheel Diameter | Φ10-Φ50MM |

| Polishing Wheel Diameter | Φ50-Φ100MM |

| Main Motor Power | 11KW |

| rotal Power | About 10 kw |

| Main Electrical Apparatus | ShnaiderQMRON |

| Max traverse speed | 25000m m/min |

| Max working speed | 15000mm/min |

| Spindle | Taiiwan.Mechanical belt spindle |

| Spindle speed | 1500-10000RPM |

| rool maezine | 24pcs |

| Working voltage | AC380V/220v |

| Command | G code |

Processing

Loading Container

Company Information

Leave A Message

Scan to wechat