What is Kerbstone Production Line?

Jan 28 , 2026

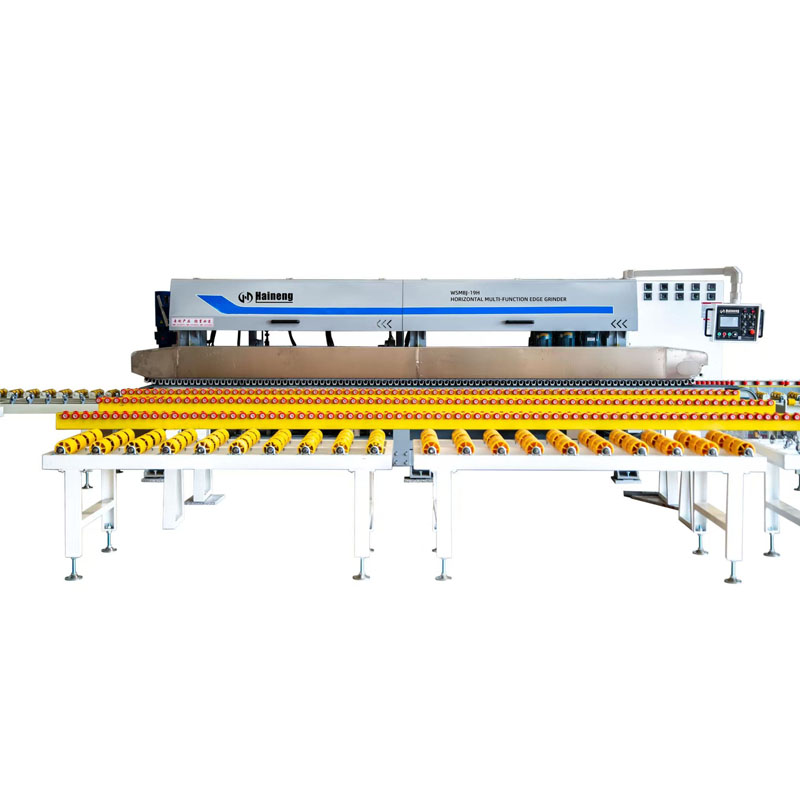

Urban development demands ever-increasing output and precision in kerbstone cutting. Haineng provides advanced end-to-end equipment solutions for kerbstone production. This curb stone machine line processes diverse materials including granite, marble, limestone, basalt, sandstone, concrete, and engineered stone to manufacture kerbstones, paving blocks, guardrails, and square semi-finished products...

Read More