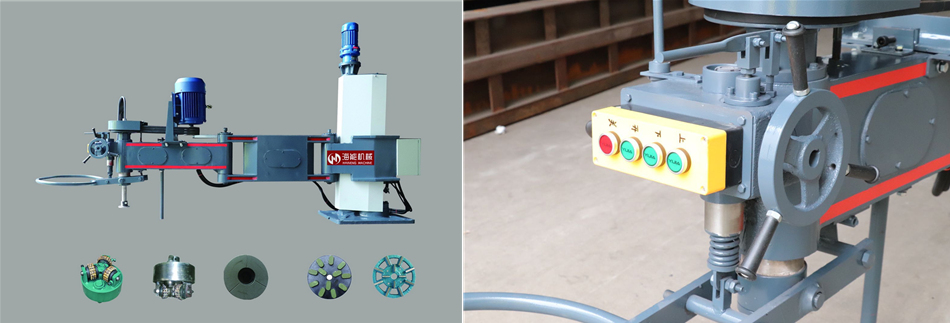

Hand stone polishing machine adopts a cylinder as the lifting guide and sliding surface, and the automatic lifting is stable. The main engine has two types of single and double speeds. It is used for surface grinding and polishing of stone slabs, tombstones, parquet stones, etc. whose thickness changes frequently. It can be equipped with a workbench to grind the inner and outer arc craft stone.

Brand:

HAINENGItem NO.:

SFM-2600BOrder(MOQ):

1Payment:

T/TProduct Origin:

ChinaColor:

Yellow & gray & OthersShipping Port:

Xiamen portLead Time:

15 daysProduct Introduction

Manual Stone Polishing Machine uses round column as its guide slip surface for steady automatic lifting up and down.The main drive has two kinds:single speed and double speeds.The machine is applicable to plane grinding and polishing of slabs with greatly various thickness,tombstones,and stone with design.The worktable can be selected for grinding crafts camber inside and outside.

A. Install a polishing plate to polish the surface of the stone.

B. Litchi surface can be processed on the plate surface by installing litchi surface.

Technical Parameters

|

Manual Stone Polishing Machine |

||

|

Type |

unit |

SFM-2600B |

|

Main motor power |

kw |

5.5 |

|

Gyro radius |

mm |

2600 |

|

Range of vertical stroke |

mm |

0-650 |

|

Grinding wheel diameter |

mm |

105 |

|

Water consumption |

m³/h |

3 |

|

Dimension (L×W×H) |

mm |

3300×1900×600 |

|

Total weight |

kg |

900 |

Worktable can optional

Milling Plate can optional

Processing

Loading photos

Company Information

Previous :

Automatic Stone Bush Hammering MachineNext :

Single Head Granite Marble Polishing MachineLeave A Message

Scan to wechat