Brand:

HAINENGItem NO.:

DFX3200-2/DFX3200-4Order(MOQ):

1Payment:

T/TProduct Origin:

ChinaColor:

yellowShipping Port:

Xiamen PortLead Time:

20 daysProduct Introduction

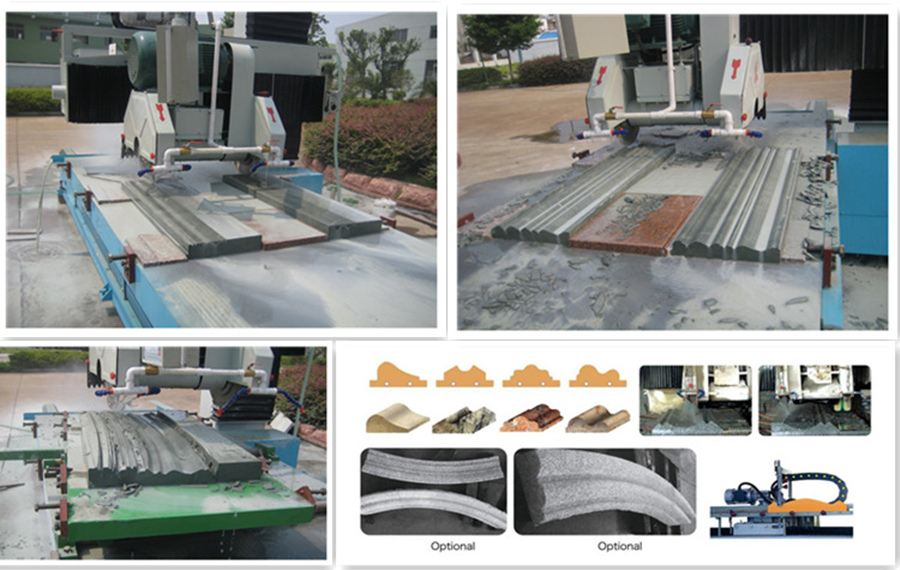

Automatic Special Shapes Profiling Cutting Machine automatically tracks the model of the curved (straight) line model through the optical soldering probe, and automatically cuts the stone crafts such as stone lines in the shape of a curved (straight) line with a diamond circular saw blade. The upper and lower lifting and the left and right passes are all frequency-converted. Speed regulation can be adjusted according to the material of the stone. For example, the rotary table can be selected, and the arc-shaped line can be processed. The Automatic Special Shapes Profiling Cutting Machine adopts PLC programmable control, high degree of automation and high cutting precision. Double-knife design and cutting efficiency High, stable and easy to operate, it is especially suitable for the processing of shaped stones such as lines, arc-shaped lines, Roman columns and large circular arc plates.

Remarks: The CNC system can be modified to eliminate the trouble of making templates, and the degree of automation and cutting accuracy is higher.

Technical Parameters

Unit

For 2 blades

For 4 blades

Max.cutting length

mm

3200

3200

Max.cuting width

mm

600X2

200X4

Max.cuting thickness

mm

300

300

Blade diameter

mm

Ø350-Ø600

Ø350-Ø600

Main motor power

kw

15

18.5

Gross power

kw

19.5

22.8

Exhausted water

m³/h

3

4.5

Gross weight

kg

3500

3600

Overall dimensions (L×W×H)

mm

5400×1900×2300

5400×2150×2500

Type

Processing

Loading container

Products Recommended

Company information

Previous :

Stone Baluster Profiling MachineNext :

CNC Stone Profiling Line Cutting Polishing MachineLeave A Message

Scan to wechat