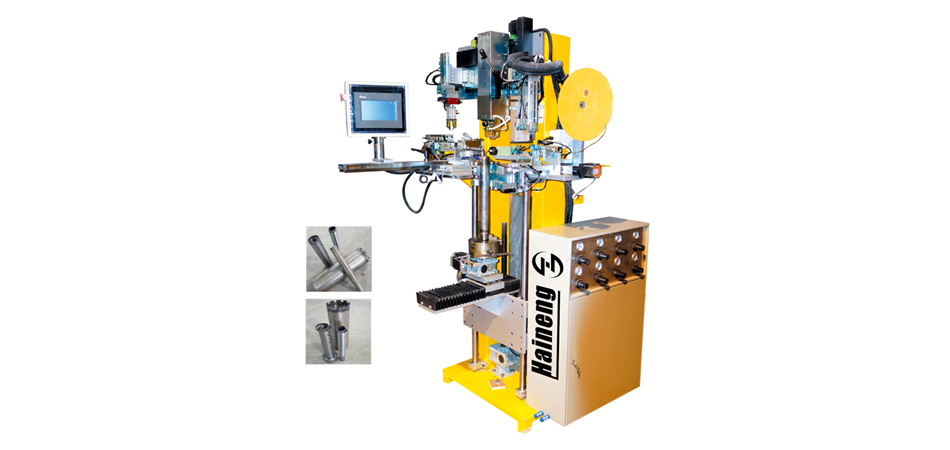

Our DQW400-EP series is high intelligen and precision machine in diamond core drill brazing . it using our innovative brazing system to make the brazing more accurate, stable and efficient.

Brand:

HAINENGItem NO.:

ZHJ-400Order(MOQ):

1Payment:

T/TProduct Origin:

ChinaColor:

yellowShipping Port:

Ningbo portLead Time:

15 daysProduct Introduction

Features

DQW400-EP series machine has our patented SACCF system (Solder Automatic Cutting Correcting Feeding system)which guarantee 100% successful feeding rate for all kinds diamond saw blade.

We use gapless brazing adjustment system and 0.01mm minimum unit fine tuning system make the brazing easy and accurate. This machine does not require high standard segment and brazing material due to the innovative design, so this machine can suit for multiple production condition and cost control requirement.

Configuration

1.Segment automatic picking & fixing system. Machine can automatic pick up the segment and fix to the brazing position.

2. Sliver solder automatic cutting Correcting & sending system.Operator can set the length of the solder in the touch screen, then machine will automatic cut off the solder and sent to the welding position. Very accurate and convenience. (Requirement: solder thickness 0.1-0.4mm width> 2.2mm)

3.Automatic soldering flux feeding system. Sliver solder and flux feeding are both independent, so they will not influence each other.

4.Laser positioning system

5. Dynamoelectric automatic segments separating system.

6.Ceramic clip protection function.

7.Error automatic stop & display system

8. Smoke cleaning system.

Optional Configuration

1.Pressure control brazing system

2.Infrared ray temperature control

3.20mm-100mm diameter segment transmission system

Technical Parameters

|

Model |

ZHJ-400 |

|

Brazing Diameter(mm) |

20~410/90~410 |

|

Concentricity Error(mm) |

100-650 |

|

Welding Error( Linearize)(mm) |

≤±0.025 |

|

Core Drill Height(mm) |

≤±0.025 |

|

Brazing Capacity(pc/h) |

240-450 |

|

Air Pressure(mpa) |

0.6 |

|

Hydraulic Pressure(mpa) |

≥0.2 |

|

Power(w) |

800 |

|

Water consumption(m3/h) |

2 |

|

Weight(kg) |

380 |

Loading container

Company information

Leave A Message

Scan to wechat