Multifunctional Rock driller is mainly used in quarrying, available for horizontal, vertical, and slantwise drilling.

Brand:

HAINENGItem NO.:

YT29A 2-YT29A 4-YT29APayment:

T/TProduct Origin:

ChinaColor:

YellowShipping Port:

Xiamen PortLead Time:

30 Days

Product Introduction

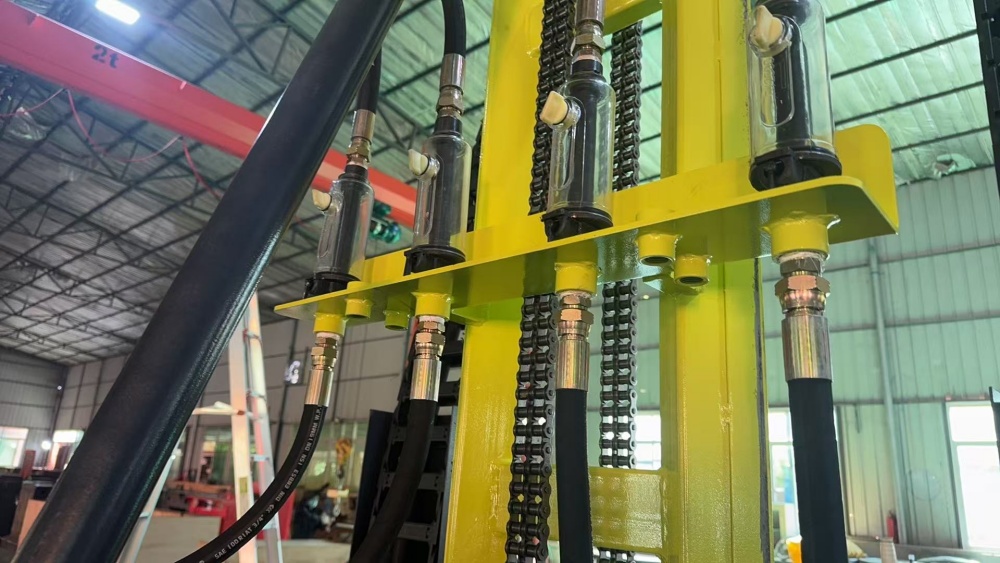

The pneumatic rock drill is a highly efficient and durable rock drilling tool that uses compressed air as its power source, primarily designed for use in quarry operations. This equipment is capable of performing horizontal, vertical, and inclined drilling operations and can divide large rock blocks into smaller pieces. Its compact design and powerful performance enable it to operate reliably in harsh environments.

Technical Parameters

|

Driller Code |

Single Hammer Rock Driller for Vertical and Horizontal Drilling |

Two-Hammer Rock Driller for Vertical and Horizontal Drilling |

Four Hammer Rock Driller for Vertical and Horizontal Drilling |

|

Hammer |

YT29A |

2-YT29A |

4-YT29A |

|

rated track length |

2*3m |

2*3m |

2*3m |

|

max.drilling depth |

1-8m |

1-8m |

1-8m |

|

drilling diameter |

34mm-42mm |

34mm-42mm |

34mm-42mm |

|

minimum air pressure |

0.6MPa |

0.6MPa |

0.7MPa |

|

drilling speed |

30m/h |

30m/h |

30m/h |

|

total compressed air consumption |

7-9m³/min |

10-12m³/min |

18-20m³/min |

|

Advance power |

1.5kw |

3kw |

6kw |

|

track travel |

3m |

3m |

3m |

|

Single advance |

2m |

2m*2 |

2m*4 |

|

Feed System |

Pneumatic motor, chain |

Pneumatic motor, chain |

Pneumatic motor, chain |

|

cross travel device |

Hand wheel, gear, rack |

Handwheel, gear, rack |

Handwheel,gear,rack |

|

drilling direction |

Any direction |

Any direction |

Any direction |

|

number of the hammer |

1 |

2 |

4 |

|

total weight |

500kg |

1000kg |

1200(kg) |

Processing

Previous :

Marble Mining Quarry Chain Saw MachineNext :

Diamond Wire Saw For Stone QuarryLeave A Message

Scan to wechat