This chain saw designed to open and develop underground mines of marble and of similar stone materials. Underground mining development is becoming a more and more common practice in many marble quarry operations. This method is often considered preferable to the open pit quarrying in terms of production optimization, efficiency, safety and environment preservation.

The machine is mounted on a crawler and it can move easily and autonomously inside the tunnel. The machine is configured as shown in the next figures to reduce the overall dimensions and to move over slopes up to 25%.

All the movements of the crawler and the positioning devices of the machine are made possible by an on-board “power pack” unit equipped with a diesel engine. During the cutting operation, the machine should be simply connected to the power line through cable and on-board plug. All the functions are controlled by means of a remote control board without cable and of a touch-screen panel.

This machine is compact for tunnel mining work. By setting the cutting depth in automatic mode, the machine can make vertical and horizontal cuts on the tunnel face.

This is self-propelled on crawler tracks and moves completely autonomously. Only one operator is required to operate the machine. This model can run cuts as deep as 1.7 meters.

Brand:

HAINENGItem NO.:

DKLJ2000/DKLJ3000Order(MOQ):

1Payment:

T/TProduct Origin:

ChinaColor:

YellowShipping Port:

Xiamen portLead Time:

20 daysProduct Introduction

Advantages of using Tunnel Chain Saw Machine

1. Don’ t need to do the large - scale stripping skin and mountain earth , it can mine the finest marble resources directly .

2. Less land acquisition and trees cutting , less slag and gravel, low cost of slagging and vegetation restoration .

3. Fast exploitation , good appearance of blocks , high blocks yield.

4. High production efficiency, it is not affected by the weather , day and night time , and it can control the mining speed progress , and has higher mining efficiency and benefit in the late stage when expanding to the left , right and downward sides.

5. Low comprehensive cost , good long - term benefits , low risks.

Technical Parameter

|

Tunnel Chain Saw Machine |

|||

|

Model |

Unit |

DKLJ2000 |

DKLJ3000 |

|

Hole size |

mm |

H4000×W4000×D2000 |

H5500×W6000×D3000 |

|

Cutting width |

mm |

40 |

40 |

|

Cutting speed |

m/h |

0~4 |

0~4 |

|

Installed power |

kw |

55 |

75 |

|

Weight |

kg |

2500 |

3500 |

|

Dimensions |

mm |

5800×2000×2800 |

6900×2530×3200 |

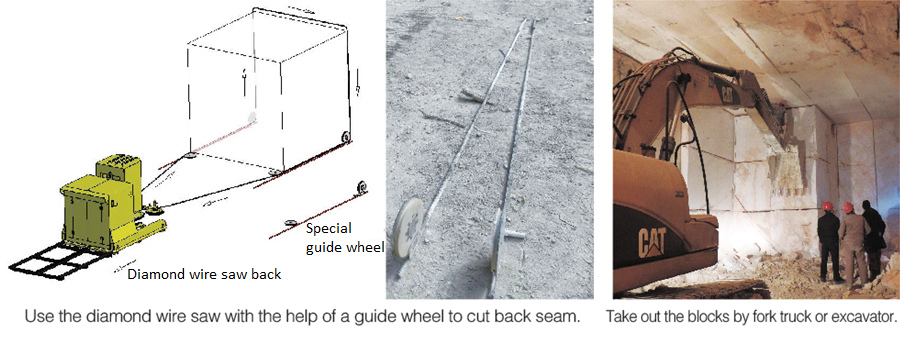

Processing

Working machine--horizontal cutting

Working machine--vertical cutting

Company information

Previous :

Rail Type Stone Quarry Chain Saw MachineLeave A Message

Scan to wechat