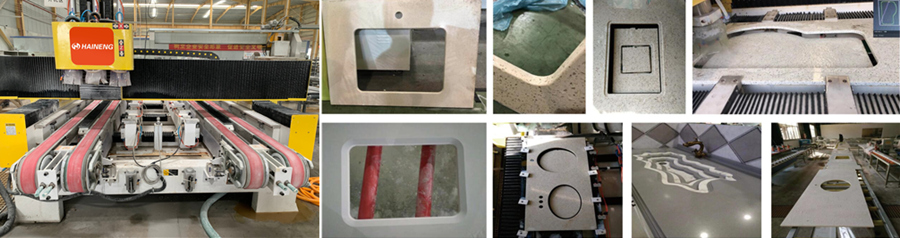

Using numerical control (CNC) principle, accurate positioning, automatic opening, automatic in and out of the plate; automatic feeding, automatic positioning, automatic clamping, automatic hole forming, automatic waste discharge and discharge.Designed for assembly line production, conveying Belt drive, high automation; electric spindle with high power and high efficiency.Complete functions, No. 1 cutter head can not only open various round holes, square holes, faucet holes, but also can process column feet, No. 2 cutter head can be shaped to meet the processing requirements for under-counter basins and Taichung basins; No. 3 cutter head can be polished, and the brightness can reach about 400 meshes.It is (currently) the most advanced countertop sink cutting machine.

Brand:

HAINENGItem NO.:

KL-3TSOrder(MOQ):

1Payment:

T/TProduct Origin:

ChinaColor:

Yellow & grayShipping Port:

Xiamen portLead Time:

15 daysProduct Introduction

Scope of application: High-performance automatic assembly line opening and chamfering equipment developed for artificial stone, quartz stone, marble and countertop processing industry.

Equipment function: the opening of the countertop stove hole, the above counter basin, the Taichung basin and the undercounter basin.

Basic processing: The equipment is welded and annealed by integral steel pipe. The machining machine is a Japanese Mazak five-axis CNC gantry milling machine, which effectively guarantees the service life and machining accuracy of the equipment.

Configuration selection: The core mechanical and electrical components are all imported or domestic first-line brands, which effectively guarantees the operational stability and quality of the equipment.

Fool-type operation: The control system is independently developed by Longhan's own software department, and the equipment can reach the fool-like operation, effectively avoiding the problem of high entry threshold caused by the low quality of the practitioners. The automatic processing of automatic feeding and discharging of the assembly line has greatly met the current development trend of the countertop industry, effectively reducing the processing dust of the factory, improving the standardization of the products, and the requirements for the operators to be used without differentiation. The design of the double station greatly improves the processing efficiency of the equipment.

Processing quality assurance: This equipment adopts three-knife automatic switching and on-line processing design, which is easy to operate, high in processing efficiency and good in quality.

This CNC Undermount Sink Cutting Machine is a necessary choice for standardized countertop processing plants, especially for engineering countertop processing plants.

Technical Parameters

|

CNC Undermount Sink Cutting Machine |

||

|

Type |

unit |

KL-3TS |

|

Width |

mm |

2800 |

|

Length |

mm |

4500 |

|

Height |

mm |

1800 |

|

Cutting slab width |

mm |

550-700 |

|

Cutting slab length |

mm |

600-2600 |

|

Cutting slab thickness |

mm |

12-20 |

|

Airway velocity parameters |

mm/min |

12000 |

|

Machining speed parameters |

mm/min |

1000-4000 |

|

Total Power Parameters |

kw |

11 |

|

Operating Voltage Parameters |

v |

AC380 |

|

Motor |

/ |

Customized 7.5KW motorized spindle |

|

Motor speed |

rpm/min |

24000 |

|

Control system |

/ |

Longhan K7026 Special Edition |

|

Tool Change Type |

/ |

Three-end pneumatic tool change |

|

Control cabinet |

/ |

Independent cabinet |

|

Frequency conversion type |

/ |

Customized Vector Frequency Converter |

|

Driver type |

/ |

Customized Servo System |

|

Feeding mode |

/ |

Automatic Pipeline |

Processing

Features

batch / special shape / more labor-saving

Suitable for processing: basin hole / stove hole / countertop middle basin

|

|

|

Non-standardized mass production |

Mass production of bathroom basins |

|

|

|

Running water trough |

High standard |

|

|

|

Change employment |

Optimized series |

Products Recommended

Previous :

Automatic Quartz Sink Hole Cutting MachineLeave A Message

Scan to wechat