Brand:

HAINENGItem NO.:

SKZ-M16Order(MOQ):

1Payment:

T/TProduct Origin:

ChinaColor:

yellow & grayShipping Port:

Xiamen portLead Time:

15 daysProduct Introduction

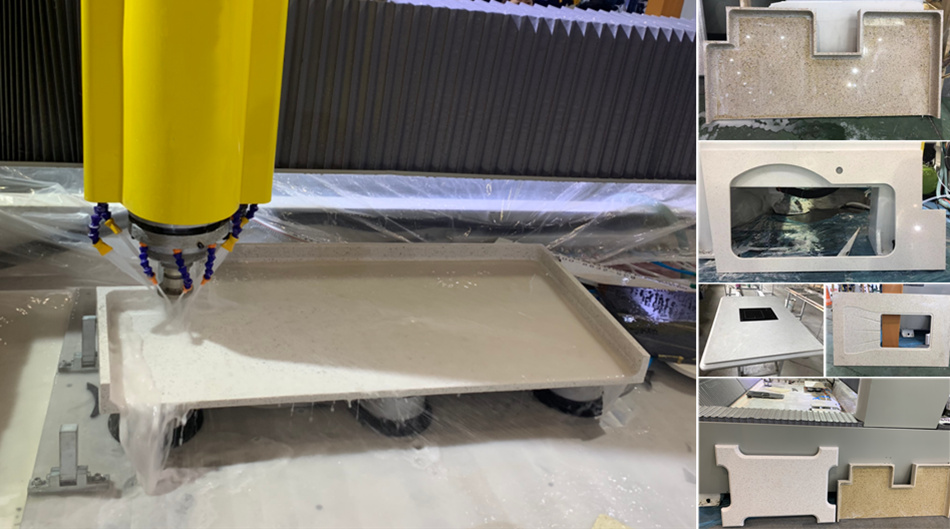

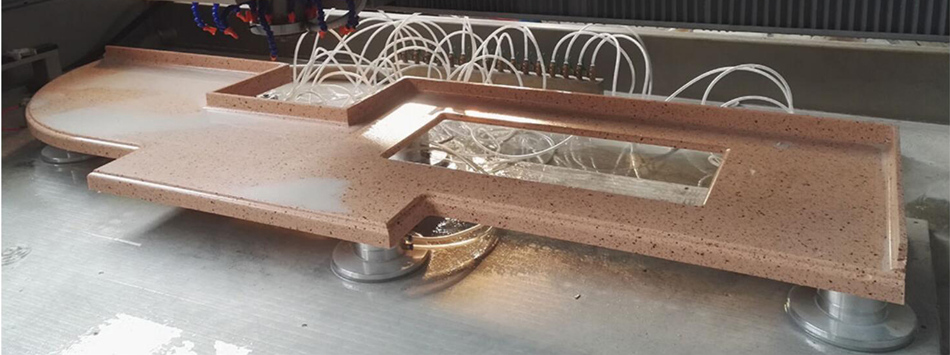

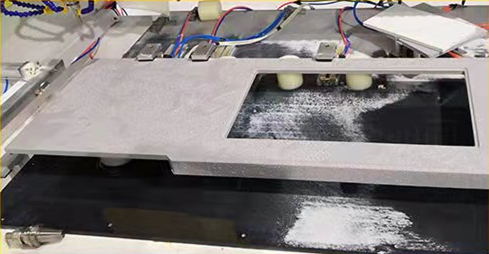

Application equipment: high-speed milling, cutting, edging, and polishing equipment developed for the slab countertops, quartz stone countertops, and marble tabletop processing industries.

Equipment function: rock slab drilling, edging, special-shaped processing; European-style edge special-shaped edging of countertops, back round bottom, countertop overflow, countertop basin, Taichung basin opening, special-shaped island, bathroom cabinet, dining table, TV cabinet , Coffee table countertops.

Basic processing: The equipment adopts integral steel pipe welding and annealing treatment. The processing mother machine is a Japanese Mazak five-axis CNC gantry milling machine, which effectively guarantees the replacement of the equipment and the processing accuracy.

Configuration substitution: The core machinery and electrical components are all imported or domestic first-line brands, which effectively guarantees the operational stability and quality of the equipment.

Fool-style operation: The control system is independently developed by Longhan's own software department, and the equipment can achieve fool-style operation, which effectively avoids the problem of high entry biology caused by the low quality of the practitioners.

Processing quality assurance: This Stone CNC machining center adopts 16 tool magazines for automatic tool change, which effectively reduces manual labor intensity and avoids manual operation errors. The automatic compensation function greatly improves the processing quality of the workpiece.

It is the first choice for high-end countertop processing plants, especially slate processing plants!

Technical Parameters

|

Stone CNC Machining Center (Automatic Tool Change) |

||

|

Type |

unit |

SKZ-M16 |

|

Shape width |

mm |

5200 |

|

Shape Length |

mm |

2600 |

|

Shape Height |

mm |

1800 |

|

Size width of Exercise itinerary |

mm |

3000 |

|

Size Length of Exercise itinerary |

mm |

1300 |

|

Size height of Exercise itinerary |

mm |

300 |

|

Airway velocity parameters |

mm/min |

20000 |

|

Machining speed parameters |

mm/min |

1000-6000 |

|

Total Power Parameters |

kw |

15 |

|

Operating Voltage Parameters |

v |

AC380 |

|

Motor |

/ |

Customized 7.5KW Tool Changer Spindle |

|

Motor speed |

rpm/min |

3000-8000 |

|

Control system |

/ |

Longhan M16 Export Edition |

|

Tool Change Type |

/ |

Waterproof design of 16 knife storehouse |

|

Control cabinet |

/ |

Independent cabinet |

|

Frequency conversion type |

/ |

Customized Vector Frequency Converter |

|

Driver type |

/ |

Customized Servo System |

|

Fixed mode |

/ |

Vacuum chuck |

Processing

One-step molding of countertops

|

Six core functions High standard equipment accuracy, user-friendly design experience |

|

|

|

|

1. Round bottom arc Easy-care water-repellent technology saves time compared to traditional production methods |

2. Grinding seams Combined with dust-free installation technology, the seams can be perfectly connected |

|

|

|

3. Drain sink

Bring owners a better experience, more choices and more possibilities

|

4. Grinding Shaped Edges Simplify the processing process, smoother production, and linearly increase efficiency |

|

|

|

5. Countertop middle and lower basin Reduce labor intensity and improve pot hole production standards |

6. Special-shaped customization Support direct import of CAD, effectively reduce costs in combination with labor |

Loading Container

Company Information

Previous :

CNC Four-Axis Cutting MachineNext :

Automatic Quartz Sink Hole Cutting MachineLeave A Message

Scan to wechat