Brand:

HAINENGItem NO.:

ZQ-1000/22*2,ZQ-1200/45*2Order(MOQ):

1Payment:

T/TProduct Origin:

ChinaColor:

YellowShipping Port:

Ningbo portLead Time:

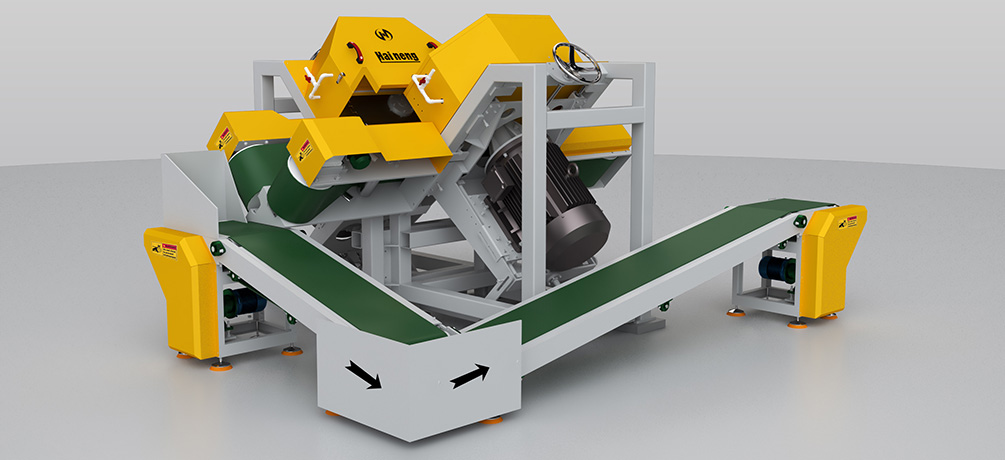

15 daysHigh Performance Integrated Double Blades Stone Thin Veneer Saw

Double Blades Stone Thin Veneer Saw Product Introduction:

The Stone Thin Veneer Saw Machine is a monolithic structure with compact structure and convenient installation and transportation.The main control components are all international brand components, and the cutting main motor and cutting conveyor belt are all stepless speed regulation.The working mode of the machine adopts the continuous cutting mode of the pipeline, which is mainly used for cutting the plane of irregular elliptical stones such as goose warm stone.

make cutting thin stone veneer flats and 90-degree corners quick, simple, and profitable. The unique v-structured cutting surface easily cuts split-face or natural finished sandstone, brick, limestone, and other hard stones up to 16" high and 2.5"thick.

The working mode of the machine adopts the continuous cutting mode of the pipeline , which is mainly used for cutting the plane of irregular elliptical stones such as goose warm stone.

Stone Thin Veneer Saw Technical Data:

|

Model |

ZQ-1000/22×2 |

ZQ-1200/45×2 |

|

|

Main Motor Power(kw) |

22kw(30HP)×2 |

|

45kw(60HP)×2 |

|

Electricity |

3 phases,380V,50Hz (Customizable) |

||

|

Amperage |

(86/43A)×2 |

|

(172/86A)×2 |

|

Water Consumption(m⊃3;/h) |

4 |

|

4 |

|

Blade Size(mm) |

800-1000 |

1000-1200 |

|

|

Blade Speed Standard(adjustable) |

Max.900rpm. |

Max.780rpm. |

|

|

Max.stone height (mm) |

0-350 |

0-450 |

|

|

Saw blade adjustable distance(up/down)(mm) |

0-120 |

0-250 |

|

|

Saw blade adjustable distance(back/forth)(mm) |

0-200 |

0-250 |

|

|

Max.stone thickness(mm) |

20-220 |

20-270 |

|

|

Conveyor Belt Length*width*thickness(mm) |

5970×280×7 |

6800×400×7 |

|

|

Conveyor Belt Speed(Adjustable)(mm/min ) |

600-2450 |

600-2450 |

|

|

Max.Cutting Depth(mm) |

280 |

350-450 |

|

|

Dimensions (L*W*H)(mm) |

3050×3000×1800 |

3550×3500×2200 |

|

|

Machine Weight(kg) |

4500 |

|

6000 |

|

|

|

|

|

|

Leave A Message

Scan to wechat